As the global economy looks to increase sustainability, there is increasing pressure on oil and gas companies to reduce their overall methane emissions. Upstream producers are looking for the most economic solutions to qualify their gas as higher value low-emission gas, meet the required regulations, or both, without driving their capital or operating costs higher than need be.

Third party certifications like the MiQ certification provide operators with a score based on the methane intensity of their operations, the number of company practices implemented that are related to methane emissions management, and their deployment of methane monitoring technologies. While these certifications are voluntary, they can increase the price and attractiveness of a company’s gas for natural gas buyers looking to achieve ESG goals by reducing their scope 3 emissions, which help to differentiate their commodity. Also, some LNG export markets such as the European Union are setting methane intensity limitations. Eliminating methane venting from pneumatics helps to meet these MiQ requirements.

Mandatory federal requirements, like the United States Environmental Protection Agency’s (EPA’s) regulation 40 CFR part 60, subpart OOOOb require new, existing or reconstructed sources of methane that were built or modified after August 23, 2011, to produce zero methane and VOC emissions from pneumatic controllers, with some limited exceptions. The gas vented from these devices must be routed back to a sales line or used for another beneficial purpose that does not involve routing to a flare or control device. Upcoming regulation from the EPA’s regulation 40 CFR part 60, subpart OOOOc will require that all existing sources follow the same restrictions and a plan to implement the emission guidelines is required by March 9, 2026, with regulatory compliance required 36 months later. Globally, methane reduction legislation is gaining traction as initiatives like the Global Methane Pledge have reached 158 participating countries and have agreed to reduce global methane emissions by at least 30% by 2030 from 2020 levels.

How Can Global Power Technologies Help?

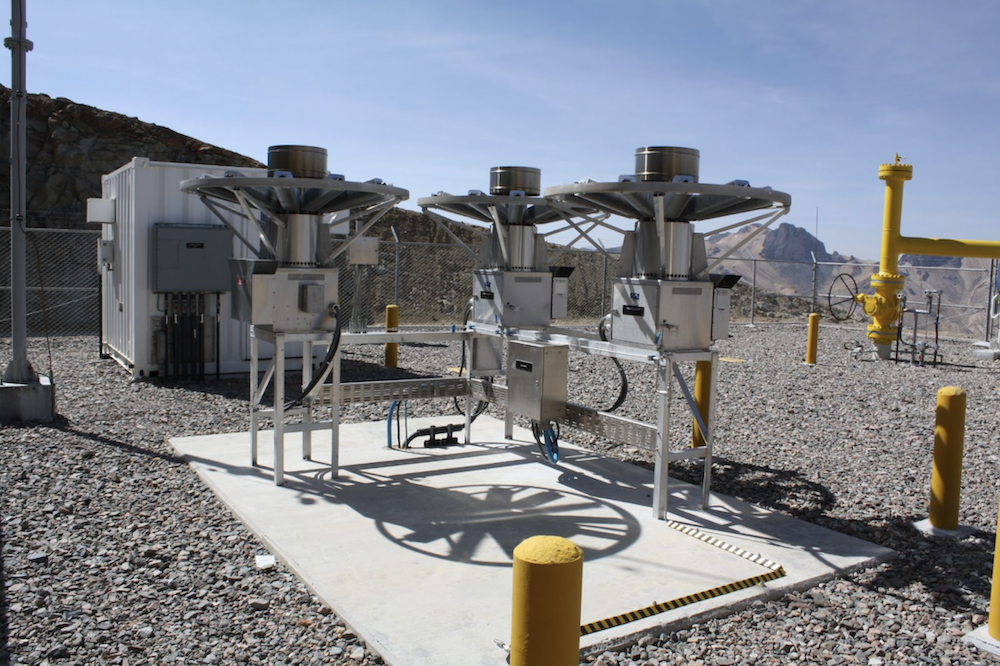

These market influences have the gas industry looking for economic solutions to reduce their overall emissions. Traditionally, one source of vented methane is from the pneumatic actuation of valves or devices and this vented gas is a common application to address in the beginning stages of methane abatement. Global Power Technologies’ thermo-electric generators (TEGs) are actively being used to repurpose vented gas from these devices to generate power and heat for sites.

In this application, the TEG uses the vented pneumatic controller gas, blended with instrument gas, for the beneficial purpose of power generation while eliminating vented gas methane and decreasing instrument gas consumption. Existing TEG installations can be modified to suit this purpose or new TEGs can be installed, with the incremental power being used for battery charging, heating or instrumentation for methane measurement and reporting.

TEGs are extremely efficient at destroying methane emissions; they destroy 99.9% of methane from the fuel gas. To eliminate the vented gas from the pneumatic controller, the emitted gas is combined through the intake regulator, which runs on instrument gas. The gas inlet from the pneumatic controller must not bypass the TEG’s gas safety valve. The manifold pressure is set so that the TEG is providing the proper voltage and the parallel instrument gas supply acts as makeup gas with the intake regulator set at the minimum pressure for the TEG.

The appropriate TEG model depends on the power requirements of each site, as well as the pressure and flow rate of vented gas. The recommended models based on low required manifold pressures are legacy 5060 or 5120 TEGs if they are already in a fleet and P-5050, P-5100 and 8550 for new TEG installations. GPT does not recommend using 5220 or S-8500 TEGs due to the higher manifold pressure requirements.

The table below can help verify a site’s pressure and flow rates compatibility with various TEG models:

For older and smaller well sites, a TEG combined with an appropriate vent gas manifold can offer the simplest and most cost effective solution to decreasing vented methane to meet both gas methane intensity certifications or regulatory requirements.

Contact us for more information on how different TEG applications can help solve your business needs.